Custom foam packaging solutions in Holland, Ohio, utilize professional design to offer tailored protection for diverse products. High-density polyethylene (HDPE) and low-density polyethylene (LDPE) foams provide distinct advantages like superior shock absorption, eco-friendliness, and cost-effectiveness. These benefits make foam packaging a preferred choice for businesses seeking reliable shipping solutions that minimize waste and support sustainability goals. Through innovative designs, custom foam packaging ensures product security, enhances brand visibility, and accommodates various shapes and sizes at a competitive cost.

Polyethylene foam packaging is a versatile and effective solution for product protection, with diverse applications across various industries. This article explores the multifaceted world of polyfoam, from understanding its materials and types to discovering the professional design that enhances its effectiveness. We delve into the benefits of foam packaging, highlighting its role in safeguarding products during transit. Furthermore, we discuss its growing adoption in different sectors and address sustainability considerations. Finally, key factors for choosing a reliable supplier for custom foam packaging solutions in Holland, Ohio, are provided.

- Understanding Polyethylene Foam Packaging: Materials and Types

- Custom Foam Packaging Solutions: Tailoring to Your Needs

- The Role of Professional Design in Effective Foam Packaging

- Benefits of Using Foam Packaging for Product Protection

- Applications: Industries Adopting Foam Packaging

- Sustainability Considerations in Foam Packaging

- Choosing the Right Supplier: Key Factors for Quality Foam Packaging

Understanding Polyethylene Foam Packaging: Materials and Types

Polyethylene foam packaging is a versatile and effective solution for various industries. Custom foam packaging solutions in Holland, Ohio, offer unique benefits that cater to specific product protection needs. The materials used play a significant role in determining the effectiveness of such packaging. High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are two primary types of foams, each with distinct properties. HDPE, known for its superior strength and durability, is ideal for heavy or delicate items requiring robust protection. On the other hand, LDPE foam is lightweight yet surprisingly resilient, making it suitable for a wide range of applications, from cushioning fragile items to providing insulation.

Professional foam packaging design involves precise engineering to create custom solutions. By understanding the material’s characteristics and the product’s requirements, designers can optimize protection while minimizing material waste. This not only offers economic benefits but also contributes to sustainability goals by ensuring efficient use of resources. The benefits of foam packaging include superior shock absorption, lightweight nature, and cost-effectiveness, making it a preferred choice for many businesses seeking reliable and eco-friendly shipping solutions.

Custom Foam Packaging Solutions: Tailoring to Your Needs

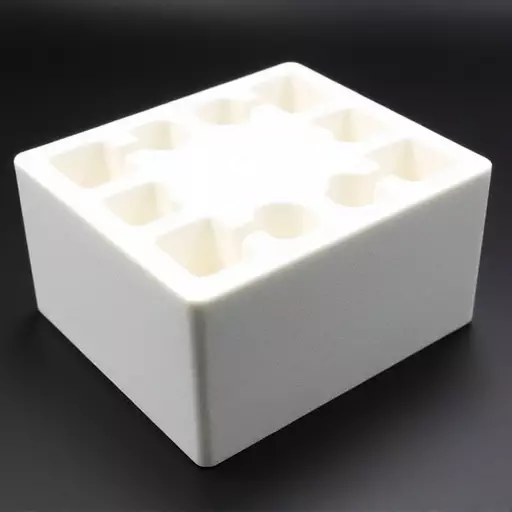

Custom Foam Packaging Solutions in Holland, Ohio, offer a unique and tailored approach to product protection. With a team of professionals dedicated to foam packaging design, they ensure each client’s specific needs are met with precision. By understanding the intricacies of various products and industries, these experts create innovative solutions that go beyond standard packaging. Custom foam inserts are designed to perfectly accommodate unique shapes and sizes, providing superior shock absorption and preventing damage during transit.

The benefits of foam packaging are numerous. It offers lightweight yet robust protection, reducing transportation costs while ensuring the safe arrival of fragile items. Custom designs can enhance brand visibility, as logos and colors can be incorporated into the foam, creating a memorable unboxing experience. Moreover, foam packaging is versatile, suitable for a wide range of products, from electronics to art pieces, making it a preferred choice for businesses seeking efficient and effective protection for their goods.

The Role of Professional Design in Effective Foam Packaging

In the realm of product protection and shipping, custom foam packaging solutions in Holland, Ohio, have emerged as a game-changer. Professional design plays a pivotal role in harnessing the full potential of foam packaging. Skilled designers understand the unique properties of various foam materials—their flexibility, shock absorption, and insulative qualities—and how to strategically utilize them for optimal product security and customer satisfaction.

By employing professional foam packaging design, businesses can unlock numerous benefits. Customized inner molds ensure that products fit snugly, minimizing movement during transit. This reduces the risk of damage, especially for delicate or fragile items. Moreover, well-designed foam packaging enhances product presentation, making it ideal for retail displays. The versatility of foam also allows for creative shaping and cutting, catering to diverse product shapes and sizes while maintaining cost-effectiveness.

Benefits of Using Foam Packaging for Product Protection

Using foam packaging offers significant advantages for product protection, making it a preferred choice among many businesses, especially those in need of custom foam packaging solutions Holland Ohio. The primary benefit lies in its ability to provide excellent shock absorption and impact resistance. This is crucial for fragile or delicate items that require extra care during transportation and handling. By encasing products within a customized foam environment, potential damage from shocks, bumps, and drops is significantly reduced.

Furthermore, professional foam packaging design allows for precise tailoring to fit specific product dimensions and shapes. This not only ensures secure containment but also minimizes the amount of packing material used, making it an eco-friendly option. The versatility of foam packaging means it can accommodate a wide range of products, from electronics and glassware to automotive parts and medical devices, ensuring they reach their destinations in pristine condition.

Applications: Industries Adopting Foam Packaging

Polyethylene foam packaging has found its way into various industries, revolutionizing how products are protected and shipped. From delicate electronics to fragile glassware, custom foam packaging solutions in Holland, Ohio, offer unparalleled protection during transit. Its versatility allows professionals in foam packaging design to create unique, tailored insulators that cater to specific product needs.

The benefits of foam packaging are numerous. It’s lightweight yet incredibly robust, making it cost-effective for shipping while ensuring goods arrive safely. Foam’s ability to absorb shocks and vibrations makes it ideal for protecting high-value or fragile items. Moreover, its insulation properties help maintain product integrity by controlling temperature during transit, a significant advantage in industries like pharmaceuticals and food service that require temperature-sensitive packaging.

Sustainability Considerations in Foam Packaging

In recent years, sustainability has become a paramount concern in various industries, and the packaging sector is no exception. Custom foam packaging solutions in Holland, Ohio, are increasingly being sought after not only for their effectiveness in protecting products during transit but also for their eco-friendly attributes. Professional foam packaging design plays a crucial role here, focusing on creating innovative and sustainable materials that minimize environmental impact without compromising product safety.

The benefits of foam packaging extend beyond its protective capabilities. By utilizing recycled content and biodegradable foams, manufacturers can significantly reduce their carbon footprint. Moreover, proper disposal and recycling practices can ensure that these foams do not end up in landfills, contributing to a circular economy. With the right professional approach, custom foam packaging solutions can offer a sustainable alternative, catering to environmentally conscious consumers while providing exceptional product protection.

Choosing the Right Supplier: Key Factors for Quality Foam Packaging

When it comes to selecting a supplier for custom foam packaging solutions in Holland, Ohio, choosing the right partner is paramount to achieving high-quality results. Look for a professional foam packaging design company that understands your unique needs and industry standards. A top-tier supplier should offer a wide range of materials and customization options, enabling you to create innovative and effective packaging tailored to your products.

Beyond material selection, consider their expertise in manufacturing processes, precision cutting, and assembly techniques. Ensure they have experience providing benefits of foam packaging, such as product protection, efficient shipping, and cost-effectiveness. Additionally, a reliable supplier will prioritize environmental sustainability, offering eco-friendly options and responsible disposal practices.